Pumping fluids that are highly viscous, abrasive, laden with solids or all of these is the daily task for the Megator Lobe Pump.

Due to a number of carefully engineered features, the Megator Rotary Lobe Pump manages such a task whilst ensuring a low life cycle cost.

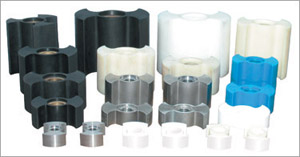

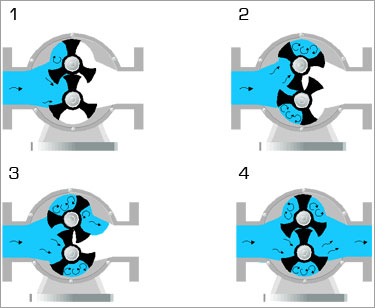

The gentle action of the two interacting rotors creates fluid movement through the pump, with minimal damage to suspended particles. Various types of rotor materials can be used, combined with a wide range of materials for all other wetted parts, resistance to wear and corrosion are obtained.

The special design of the Megator Lobe pump allows dry running, as the standard mechanical/lip - seal system is constantly lubricated. The same lubrication acts as a seal detector, allowing the user to react swiftly in case of any leaks occurring.

Typical fluids handled with the Megator Lobe Pump are:

Sludge with high dry-matter content, mud slurries, chemicals, centrifuge feed fluid, meat offal, cement slurry, gypsum, sauces with vegetables, marmalade etc.

Applications include Oil, Wastewater, Sludge, Chemicals, Asphalt, Excretions, Paints, and Polymers.

| Model | Inlet/ Outlet Dia. | Pressure bar g |

Flow (litres/min) | ||||||

| Vane | 960rpm | 725rpm | 580rpm | 480rpm | 380rpm | Per1rev | |||

| MLP-L20 | 25 | 10 | 2 | 62 | 47 | 38 | 31 | 25 | 64cc |

| MLP-L25 | 25 | 15 | 2 | 82 | 62 | 50 | 41 | 33 | 85cc |

| MLP-L32 | 32 | 15 | 2 | 105 | 79 | 64 | 53 | 42 | 109cc |

| MLP-L40 | 40 | 30 | 2 | 214 | 161 | 129 | 107 | 85 | 222cc |

| MLP-L50 | 50 | 30 | 2 | 300 | 227 | 181 | 150 | 119 | 312cc |

| MLP-L65 | 65 | 30 | 2 | 400 | 302 | 242 | 200 | 158 | 416cc |

| MLP-L80 | 80 | 30 | 2 | 519 | 415 | 343 | 272 | 715cc | |

| MLP-L100 | 100 | 30 | 2 | 728 | 575 | 475 | 377 | 990cc | |

| MLP-L120 | 125 | 30 | 2 | 1037 | 830 | 687 | 544 | 1430cc | |

| MLP-L125 | 125 | 30 | 2 | 1506 | 1205 | 997 | 790 | 2077cc | |

| MLP-L150 | 150 | 30 | 2 | 2034 | 1627 | 1347 | 1066 | 2805cc | |

| MLP-L200 | 200 | 30 | 2 | 2978 | 2466 | 1953 | 5137cc | ||

| MLP-L250 | 250 | 30 | 2 | 4172 | 3453 | 2733 | 7192cc | ||

Applications include Dairy, Bakery, Meats, Canned Foods, Beverages, Candy, Flavourings, Dressings and Cosmetics.

| Model | Inlet/ Outlet Dia. | Pressure bar g |

Flow (litres/min) | ||||||

| Vane | 960rpm | 725rpm | 580rpm | 480rpm | 380rpm | Per1rev | |||

| MLP-1S | 23 | 15 | 2 | 92 | 69 | 56 | 46 | 37 | 95cc |

| MLP-1.5S | 35.7 | 15 | 2 | 135 | 102 | 82 | 68 | 54 | 140cc |

| MLP-1.5SL | 35.7 | 30 | 2 | 279 | 211 | 169 | 140 | 111 | 290cc |

| MLP-2S | 47.8 | 30 | 2 | 356 | 269 | 215 | 178 | 141 | 370cc |

| MLP-2SL | 47.8 | 30 | 2 | 428 | 343 | 284 | 225 | 590cc | |

| MLP-2.5SL | 60.5 | 30 | 2 | 515 | 412 | 341 | 270 | 710cc | |

| MLP-3S | 72.3 | 30 | 2 | 638 | 511 | 423 | 335 | 880cc | |

What precautions should be taken when handling abrasive slurries?

Select a large pump, running at low speed. The circumferential speed of the rotor is very important, to minimize wear between rotor and casing use a hardened casing to create the best possible wear resistance, together with rotor materials that can withstand the abrasion.

What precautions should be taken when handling high viscosity fluids?

Make sure that the pump will be filled up. This is achieved by selecting a pump with large ports, which allows the fluid to fill the pump chambers. Running the pump at low speed gives the fluid enough time to enter the pump chambers.

If a satisfactory degree of filling can not be obtained by gravity or pressuring the fluid source tank, an in-feed screw may be required.

Install the pump as close as possible to the fluid source, avoiding unnecessary restrictions.

If these issues are not addressed, the pump may cavitate which will increase wear and may inflict damage to the pump.

Can the pump withstand dry running?

The lobe pump may dry run, as there is no physical contact between rotors and casing. The seal chamber is filled with a lubricant, that will not let the seals dry run, but keep them lubricated at all times. Further to this the lubricant will transmit heat generated away from the seals.

How can I minimize the pressure drop?

Use long elbows, and large diameter pipes. Use as few elbows as possible. In certain cases lubricants can be added to the fluid, thereby decreasing the pressure drop.

One should remember that the pipe system is a one-time cost - the increased running cost caused by high pressure is a continuous cost through the complete life span of the pump.

Megator