-

About

Your Best Source For Diaphragm Pumps

From Australian Mines to Manufacturing Facilities & Construction Sites Worldwide Pumps 2000 was established in Australia in 1989 to offer pumps capable of handling abrasive, solid-laden and corrosive fluids in underground mining environments, and to create an alternative to the heavy, maintenance-intensive diaphragm pumps that were used predominantly in mines. These pumps featured low weight, as well as improved pump life and performance.

Pumps 2000 Western Europe was established in 2016 to market Pumps 2000 products and solutions throughout Western Europe. Today, our pumps continue to be used in coal and hard-rock mining throughout Europe, as well as in General Industry, Marine, Building & Construction, Food Processing, Chemicals and Pollution Control applications.

Pumps 2000 pumps are assembled and tested at our facility in the United Kingdom. From this location, we also provide comprehensive technical support to our distributors, agents and end-users across Europe, and operate a service facility and warehouse to ensure fast delivery of pumps and spares.

Several patented features make it possible for Pumps 2000 to offer market-leading low life cycle cost, while handling difficult applications. A number of products are currently under development.

All Pumps 2000 products are certified in accordance with ATEX.

The use of injection molding has given Pumps 2000 greater freedom in material composition and has led to the development of lubrication-free pumps and our own plastic blends. Our unique combination of in-house R & D and manufacturing enables us to offer pumps and pumping systems which are technically superior and significantly higher quality than our competitors.

-

Diaphragm Pumps

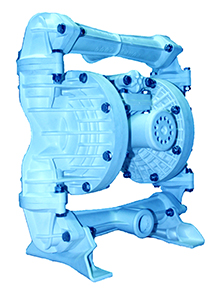

Pumps 2000 offers a wide range of patented, air-operated, non-metallic dual-diaphragm pumps that out-perform and outlast all others.

Pumps 2000 pumps are made of engineered plastics. Several patented features make it possible for Pumps 2000 to offer market-leading low life cycle cost while delivering outstanding performance in the harshest environments as these pumps were designed specifically to handle abrasive, solid-laden and corrosive fluids.

Whether your application is related to General Industry, Marine, Mining, Building and Construction, Food Processing, Chemicals or Pollution Control, there's a Pumps 2000 solution that's right for your particular needs.

Key characteristics and advantages include:

Large Particle Handling

Pumps 2000's unique slurry pumps allow particles of various types and sizes to pass through the pump unobstructed. If there's enough liquid to carry the solids, Pumps 2000 slurry pumps get the job done. To see a pump in action, view the demonstration video.

Long-Life Operation

Pumps 2000 uses the toughest engineering-grade plastics to give your pumps longer working life under the harshest conditions. By using only the best materials and patented design components, you get trouble-free operation for extended periods of time. Because Pumps 2000 pumps are made of plastic and contain stainless steel components that are ideal for corrosive environments, you'll save on maintenance and labor costs, as well as vehicle transportation and maintenance, while improving the overall efficiency of your operation.

Light Weight

Pumps 2000's air-operated double diaphragm pumps reduce the risk of lifting-related workplace injuries. Their light weight allows you to re-locate and maintain pumps quickly and easily. Keep your workers safe and happy with equipment and systems from Pumps 2000 America.

Efficient Air Usage

With a lower air consumption-to-output ratio, Pumps 2000 air-operated double diaphragm pumps do a better job using less air than traditional pumps. This benefit can lead to savings on your compressor and leave you with "excess" air that can be used elsewhere in your operation.

Lubrication-Free

Pumps 2000 pumps use plastic components that are low-wear and low-friction to give you lubrication-free, long-life operation. Save on oil, time and labor expenses used to maintain lubricators. Also save on spare parts and protect the environment from oil pollution.

Setup Versatility

Our high-suction lift in Pumps 2000 air-operated double diaphragm pumps gives you maximum flexibility when configuring pumping systems. With Pumps 2000 equipment and systems, you can keep the pumps away from high-traffic areas while continuing to get reliable priming and performance, even when they're fully submerged. We also offer assistance with pump selection and setup.

Ease of Maintenance

Pumps 2000's air-operated double diaphragm pumps contain a minimal number of components. Because they contain few parts, you'll have no headaches when it comes to maintenance.

To maintain your Pumps 2000 pumps properly, or for other information about the safe and effective operation of your Pumps 2000 equipment or systems, ask us for assistance.

-

Diaphragm Pumps

Yellow Series

Pumps 2000 Yellow Series air operated double diaphragm pumps are ATEX certified pumps, suitable for general water and slurry conditions, salt water, some low PH acid applications, applications requiring food grade approved materials of construction and more.

The Yellow series has an ATEX M2 rating. The pump housing is made of a nylon blend and the internal elastomers are hytrel. Other materials are available to suit your specific application. Please contact us with your application details so that we may select the right mix of materials for your specific application.

Ball vs Slurry Valve Comparison

High Volume Series

HV100SY - 4” / 100mm High Volume Slurry Valve Yellow Series

See our Dual Diaphragm, 4” Pumps 2000 Slurry in action.

- 307 lbs / 139.3kg Pump Weight

- Passes suspended solids up to 3” on HV 4” pump

- Maximum flow rate of 0-540 gpm

- Up to 100 psi Supply Air Pressure

- No Lubrication Required

- Self Priming

HV75BY - 3” / 75mm High Volume Ball Valve Yellow Series

See our new Dual Diaphragm, 3" Ball Valve Pump in action.

- 287lbs / 130.2kg Pump Weight

- Passes solids up to 1.3" / 33mm

- Maximum flow rate of 416 gpm / 1,575 lpm

- Up to 200ft / 61m of head at 100 psi Supply Air Pressure

- No Lubrication Required

- Self Priming

Portable Series

P75BY – 3” / 75mm Ball Valve Yellow Series

- Tested at 100 psi supply air pressure (Not to exceed 125 psi)

- 64 lbs / 29kg Pump Weight

- Passes suspended solids up to 0.71" / 18mm diameter

- Maximum flow rate of 0-215 gpm / 814 L/min

- No Lubrication Required

- Self Priming

P50SY - 2” / 50mm Slurry Valve Yellow Series

- 51lbs / 23.1kg Pump Weight

- Passes suspended solids up to 1.7" / 46mm spherical

- Maximum flow rate of 146 gpm / 553 lpm

- Up to 200ft / 61m of head at 100 psi Supply Air Pressure

- No Lubrication Required

- Self Priming

P50BY - 2” / 50mm Ball Valve Yellow Series

- 58lbs / 26.3kg Pump Weight

- Passes suspended solids up to 0.7" / 18mm spherical

- Maximum flow rate of 155 gpm / 586 lpm

- Up to 200ft / 61m of head at 100 psi Supply Air Pressure

- No Lubrication Required

- Self Priming

P40BY – 1.5” / 40mm Ball Valve Yellow Series

- Tested at 100 psi supply air pressure (Not to exceed 125 psi)

- 43 lbs / 19.5kg Pump Weight

- Passes suspended solids up to .55” / 14mm diameter

- Maximum flow rate of 0-117 gpm / 443 L/min

- No Lubrication Required

- Self Priming

P25SY - 1” / 25mm Slurry Valve Yellow Series

- 17lbs / 7.7kg Pump Weight

- Passes suspended solids up to 0.8" / 20mm spherical

- Maximum flow rate of 58 gpm / 222 lpm

- Up to 200ft / 61m of head at 100 psi Supply Air Pressure

- No Lubrication Required

- Self Priming

P25BY - 1” / 25mm Ball Valve Yellow Series

- 18lbs / 8.2kg Pump Weight

- Passes suspended solids up to 0.3" / 8mm spherical

- Maximum flow rate of 58 gpm / 222 lpm

- Up to 200ft / 61m of head at 100 psi Supply Air Pressure

- No Lubrication Required

- Self Priming

P15BY - ½” / 15mm Ball Valve Yellow Series

- 10lbs / 4.5kg Pump Weight

- Passes suspended solids up to 0.2" / 6mm spherical

- Maximum flow rate of 16.4 gpm / 62 lpm

- Up to 200ft / 61m of head at 100 psi Supply Air Pressure

- No Lubrication Required

- Self Priming

High Head Series

.jpg)

HH50BY - 2” / 50mm Double Staged Ball Valve Yellow Series

- Tested at 100 psi supply air pressure (Not to exceed 125 psi)

- 109 lbs. / 49.4 kg Pump Weight

- Passes suspended solids up to .71" / 18mm diameter

- Maximum flow rate of 0-80 gpm / 300 L/min

- No Lubrication Required

- Self Priming

HH50SY - 2” / 50mm Double Staged Slurry Valve Yellow Series

- Tested at 100 psi supply air pressure (Not to exceed 125 psi)

- 101 lbs. / 45.8 kg Pump Weight

- Passes suspended solids up to 1.5" / 40mm diameter

- Maximum flow rate of 0-80 gpm / 300 L/min

- No Lubrication Required

- Self Priming

-

Industries

The Pumps 2000 dual diaphragm pump is the first complete redesign of the diaphragm pump providing greater capabilities, reliable performance with significantly less downtime and maintenance, lower air consumption, low noise levels and light weight. Pumps 2000 is ideal for the following applications:

Select an industry

-

Diaphragm Pumps

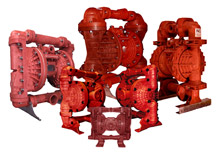

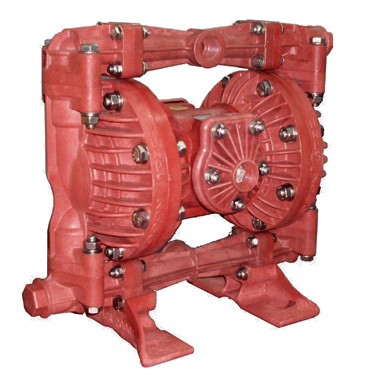

Red FRAS (Fire-Retardant Anti-Static) Series

Pumps 2000 FRAS Red Series air operated double diaphragm pumps are ATEX certified pumps suitable for continuous use in hazardous Explosive atmospheres. FRAS Series pumps are Fire Resistant & Anti-Static.

The Red Series has an ATEX M1 rating. The pump housing is made of a nylon blend and the internal elastomers are hytrel. Other materials are available to suit your specific application. Please contact us with your application details so that we may select the right mix of materials for your specific application.

Ball vs Slurry Valve Comparison

P75BR – 3” / 75mm Ball Valve Red Series

- Tested at 100 psi supply air pressure (Not to exceed 125 psi)

- 75 lbs / 34kg Pump Weight

- Passes suspended solids up to 0.71" / 18mm diameter

- Maximum flow rate of 0-215 gpm / 814 L/min

- No Lubrication Required

- Self Priming

P50SR - 2” / 50mm Slurry Valve Red Series

- 60lbs / 27.2kg Pump Weight

- Passes suspended solids up to 1.7" / 46mm spherical

- Maximum flow rate of 146 gpm / 553 lpm

- Up to 200ft / 61m of head at 100 psi Supply Air Pressure

- No Lubrication Required

- Self Priming

P50BR - 2” / 50mm Ball Valve Red Series

- 68lbs / 30.8kg Pump Weight

- Passes suspended solids up to 0.7" / 18mm spherical

- Maximum flow rate of 155 gpm / 586 lpm

- Up to 200ft / 61m of head at 100 psi Supply Air Pressure

- No Lubrication Required

- Self Priming

P40BR - 1.5” / 40mm Ball Valve Red Series

- Tested at 100 psi supply air pressure (Not to exceed 125 psi)

- 50 lbs / 22.7kg Pump Weight

- Passes suspended solids up to .55” / 14mm diameter

- Maximum flow rate of 0-117 gpm / 443 L/min

- No Lubrication Required

- Self Priming

P25SR - 1” / 25mm Slurry Valve Red Series

- 20lbs / 9.1kg Pump Weight

- Passes suspended solids up to 0.8" / 20mm spherical

- Maximum flow rate of 58 gpm / 222 lpm

- Up to 200ft / 61m of head at 100 psi Supply Air Pressure

- No Lubrication Required

- Self Priming

P25BR - 1” / 25mm Ball Valve Red Series

- 21lbs / 9.5kg Pump Weight

- Passes suspended solids up to 0.3" / 8mm spherical

- Maximum flow rate of 58 gpm / 222 lpm

- Up to 200ft / 61m of head at 100 psi Supply Air Pressure

- No Lubrication Required

- Self Priming

P15BR - ½” / 15mm Ball Valve Red Series

- 12lbs / 5.4kg Pump Weight

- Passes suspended solids up to 0.2" / 6mm spherical

- Maximum flow rate of 16.4 gpm / 62 lpm

- Up to 200ft / 61m of head at 100 psi Supply Air Pressure

- No Lubrication Required

- Self Priming

High Head Series

.jpg)

HH50BR - 2” / 50mm Double Staged Ball Valve Red Series

- Tested at 100 psi supply air pressure (Not to exceed 125 psi)

- 128 lbs. / 58.1 kg Pump Weight

- Passes suspended solids up to .71" / 18mm diameter

- Maximum flow rate of 0-80 gpm / 300 L/min

- No Lubrication Required

- Self Priming

HH50SR - 2” / 50mm Double Staged Slurry Valve Red Series

- Tested at 100 psi supply air pressure (Not to exceed 125 psi)

- 118 lbs. / 53.5 kg Pump Weight

- Passes suspended solids up to 1.5" / 40mm diameter

- Maximum flow rate of 0-80 gpm / 300 L/min

- No Lubrication Required

- Self Priming

-

Blue Series

Pumps 2000 Blue Series pneumatic diaphragm pumps are ATEX certified pumps suitable for a wide range of acids, caustics and other chemicals. The Blue series pump housing is made of a polypropylene blend and the internal elastomers are santoprene. Other materials are available to suit your specific application. Please contact us with your application details so that we may select the right mix of materials for your specific application.

P75BB – 3” / 75mm Ball Valve Blue Series

- Tested at 100 psi supply air pressure (Not to exceed 125 psi)

- 53 lbs / 24kg Pump Weight

- Passes suspended solids up to 0.71" / 18mm diameter

- Maximum flow rate of 0-215 gpm / 814 L/min

- No Lubrication Required

- Self Priming

P50SB - 2” / 50mm Slurry Valve Blue Series

- Tested at 100 psi supply air pressure (Not to exceed 125 psi)

- 42lbs / 19kg Pump Weight

- Passes suspended solids up to 1.5" / 38mm diameter

- Maximum flow rate of 0-146 gpm / 553 L/min

- No Lubrication Required

- Self Priming

P50BB - 2” / 50mm Ball Valve Blue Series

- Tested at 100 psi supply air pressure (Not to exceed 125 psi)

- 48lbs / 21.8kg Pump Weight

- Passes suspended solids up to 0.71" / 18mm diameter

- Maximum flow rate of 0-155 gpm / 586 L/min

- No Lubrication Required

- Self Priming

P40BB - 1.5” / 40mm Ball Valve Blue Series

- Tested at 100 psi (Not to exceed 125 psi)

- 36 lbs / 16.3kg Pump Weight

- Passes suspended solids up to .55” / 14mm diameter

- Maximum flow rate of 0-117 gpm / 443 L/min

- No Lubrication Required

- Self Priming

P25SB – 1” / 25mm Slurry Valve Blue Series

- Tested at 100 psi supply air pressure (Not to exceed 125 psi)

- 14lbs / 6.4kg Pump Weight

- Passes suspended solids up to 0.8" / 20mm diameter

- Maximum flow rate of 0-58 gpm / 222 L/min

- No Lubrication Required

- Self Priming

P25BB - 1” / 25mm Ball Valve Blue Series

- Tested at 100 psi supply air pressure (Not to exceed 125 psi)

- 15lbs / 6.8kg Pump Weight

- Passes suspended solids up to 0.3" / 8mm diameter

- Maximum flow rate of 0-58 gpm / 222 L/min

- No Lubrication Required

- Self Priming

P15BB - ½” / 15mm Ball Valve Blue Series

- Tested at 100 psi supply air pressure (Not to exceed 125 psi)

- 8lbs / 3.6kg Pump Weight

- Passes suspended solids up to 0.2" / 6mm diameter

- Maximum flow rate of 0-16.4 gpm / 62 L/min

- No Lubrication Required

- Self Priming

-

Diaphragm Pumps

Ebony Series

Pumps 2000 Ebony Series are available in 1 inch ball valve and 2 inch ball valve models and are ideal for pumping higher concentrations of certain acids and other chemicals. Other materials are available to suit your specific application. Please contact us with your application details so that we may select the right mix of materials for your specific application

.jpg)

P50BE - 2” / 50mm Ball Valve Ebony Series

- 55lbs / 24.9kg Pump Weight

- Passes suspended solids up to 0.7" / 18mm spherical

- Maximum flow rate of 155 gpm / 586 lpm

- Up to 200ft / 61m of head at 100 psi Supply Air Pressure

- No Lubrication Required

- Self Priming

P40BE - 1.5” / 40mm Ball Valve Ebony Series

- Tested at 100 psi (Not to exceed 125 psi)

- 41 lbs / 18.6kg Pump Weight

- Passes suspended solids up to .55” / 14mm diameter

- Maximum flow rate of 0-117 gpm / 443 L/min

- No Lubrication Required

- Self Priming

.jpg)

P25BE - 1” / 25mm Ball Valve Ebony Series

- 17lbs / 7.7kg Pump Weight

- Passes suspended solids up to 0.3" / 8mm spherical

- Maximum flow rate of 58 gpm / 222 lpm

- Up to 200ft / 61m of head at 100 psi Supply Air Pressure

- No Lubrication Required

- Self Priming

P15BE - ½” / 15mm Ball Valve Ebony Series

- 10lbs / 4.5kg Pump Weight

- Passes suspended solids up to 0.2" / 6mm spherical

- Maximum flow rate of 16.4 gpm / 62 lpm

- Up to 200ft / 61m of head at 100 psi Supply Air Pressure

- No Lubrication Required

- Self Priming

-

Diaphragm Pumps

Accessories

Pumps 2000 also has a number of accessories to help you with your pumping applications including suction strainers, float switches, air line diverter (debre trap) and general hose & fitting extras. Please contact us for more assistance in pump selection and setup advice.

Adjustable and Pneumatic Water Monitor Float Switch

- Save on compressed air and maintenance costs

- Reduced CO2 emissions

- Reduction in labour (reduced pump change outs)

- Light weight

- Efficient reliable operation

- No lubrication Required

- Anti-Static rear housing ensures continuity of FRAS hosing

- Plastic and stainless steel construction (non-corrosive)

- Simple to use and maintain

Air Particulate Diverter

Fitted to the air inlet of the Pumps 2000 diaphragm pump the Air Diverter will trap debre from the air-line at the bottom of the diverter body ready for purging. This can save you the trouble and expense associated with damaging the internal air motor of a pump due to common air-line particulate.

Quick Strainer

A convienient suction strainer with a 2 inch External Thread Connection also with a 1/2 inch External Thread breather connection.

Square Slurry Strainer

Designed to be used with the Slurry Valve pumps. The Square slurry strainer is designed to sit in the sump bottom and has 7/16" holes. This allows for coal fines and larger solids to be pumped in conjunction with liquid. Also includes breather hose that allows air to enter and aid in pump suction. Available in 1 & 2" sizes.

Dolphin Floating Strainer

A floating strainer made of durable polyurethane with stainless hardware. Closed cell foam in the hate ensures flotation even if cracked and foam becomes wet. Has 3/16" strainer holes. A perfect complement to Ball Valve pumps for dewatering applications. Available in 1.5, 2, 3, 4 & 6" sizes.

Rib Bracket (for hanging)

A hanging apparatus that will put the pump on a wall and away from potential damage from a mine vehicle or scoop.

Pump Cages

Protective devices to prevent damage from impact in mining environments.

Contact us for more information.

-

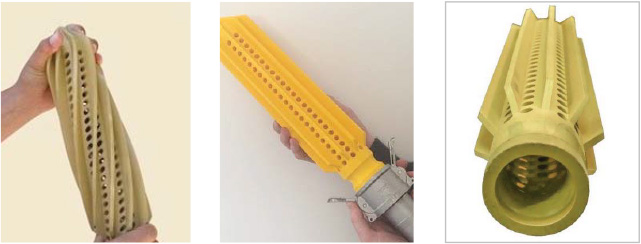

Reflex Strainer

- Underground and open cut development areas affected by excess water

- Roadways subject to constant inundation with water

- Any mining areas with high levels of water affecting production

- The mining hose with flexible strainer is simply laid on the ground in the water affected zone and pumping may commence

- No steel parts, bore holes or infrastructure needed from suction area to pump

- The product uses vulcanised polymers eliminating sharp edges and reducing hand injuries (no metal) inherent in normal metal strainers

- Removal of submersible steel objects and sharp objects, reducing trip and cut hazards

- Lightweight and flexible design, meaning less impact on personnel and machinery when in contact

- Quick and easy to clean, so personnel will spend less time in heavy traffic areas repairing or replacing equipment

- Does not corrode, therefore reduced replacement required

- Sustains many heavy contacts without breaking allowing the part to last longer

- Longer-lasting parts protect the pumps for longer periods, leading to less downtime, personnel intervention and repair and maintenance

- No need to drill costly bore holes and associated equipment in development roadways as the product can be used directly on roads and in direct contact with machinery

- More cost-effective pumps can be used keeping operating and capital costs down (diaphragm v submersible)

- Vulcanized elastomeric compound

- Manufactured in accordance to ISO9001

- Supports in excess of 100 tonnes of downward pressure

- Fast attachment / detachment to Camlock fitting

- No hose clamp required for hose tail fitting

- Vulcanized elastomeric compound

- Manufactured in accordance to ISO9000

- Supports in excess of 100 tonnes of downward pressure

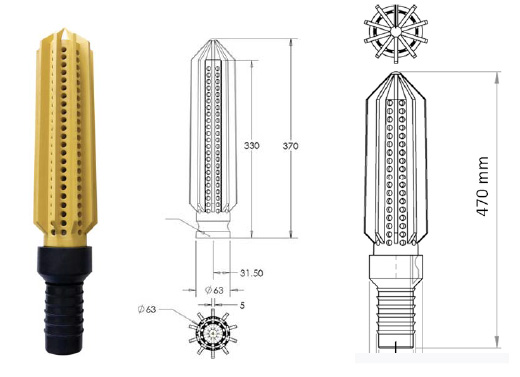

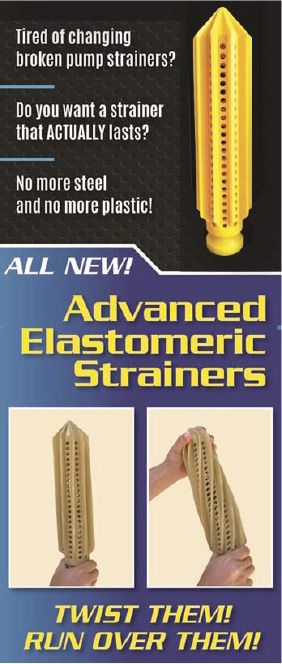

Advanced Flexible De-Watering and Filtration Devices for Harsh Environments

Born out of the high demands of the Australian underground mining environment, the Reflex Suction Strainer is designed to survive in hostile and high traffic environments. Moulded from an advanced blend of polymer rubbers, the Reflex Suction Strainer can handle extreme conditions including being run over by vehicles and machinery. The Reflex Suction Strainer costs less than conventional strainers, also saves time in cleaning and replacements. Reflex Suction Strainers are safe to use and manufactured in accordance to ISO:9001.

Applications

Safety

Cost Savings

Specifications

Flow rate 850 litres per minute Hole Size 8mm Filtration flow 12 times surface area to suction aperture Elongation Safe capability 450% Length 370mm or 470mm with hose tail Width 63mm Weight approx. 550g with hose tail 700g Hardness 60 - 70 shore A Temperature range Safe -66c to 100+c Colours Black / Yellow Reflex Hose Tail Attachment

Specifications

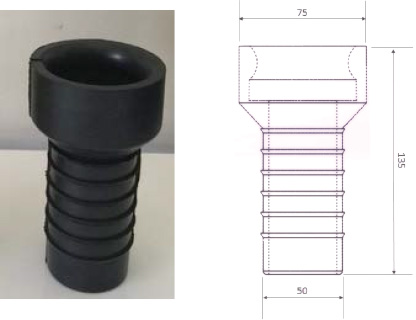

Flow rate 850 litres per minute Elongation Safe capability 450% Length 135mm Width 75mm Weight approx. 150g Hardness 90 shore A Temperature range Safe -66c to 100+c Size 2” (51mm) standard other sizes available on request

- About

- Products Overview

- Industries

- Yellow Series

- Red FRAS Series

- Blue Series

- Ebony Series

- Reflex Strainer

- Accessories

- Contact

- View all products

-

HV 4” / 100mm Slurry Valve Video

HV 3” / 75mm Ball Valve Video

2” / 50mm Ball Valve Pumping Video

2” Slurry Valve Pump

1.5” / 40mm Ball Valve Pumping Video

Two Stage 2” / 50mm Slurry Pumping Video

News & Highlighted Videos

High Volume 4” / 100mm Slurry Pump in Action

2” / 50mm Ball Valve Pumps in Action

- Mining Applications Industrial & Maritime HV 4” / 100mm Slurry Valve Video HV 3” / 75mm Ball Valve Video 2” / 50mm Ball Valve Pumping Video 2” Slurry Valve Pump 1.5” / 40mm Ball Valve Pumping Video Two Stage 2” / 50mm Slurry Pumping Video

- Mining Applications Industrial & Maritime 2” Slurry Valve Pump

- Mining Applications Industrial & Maritime 2” Slurry Valve Pump

- Mining Applications Industrial & Maritime

- Float Switch Set-up Video

-

View Our Corporate Video

-

Reflex Strainer Resources

Reflex Strainer Pumping Sump Reflex Strainer v Coal Tram Reflex Strainer v SMV Reflex Strainer v Tractor 2” / 50mm Diaphragm Pump and Reflex Strainer Twisting Reflex Suction Strainer

Megator